Supporting Subheading

High-quality downdraft tables, downdraft booths, and other air filtration equipment provide thousands of domestic and international customers with safety relief.

The DualDraw Downdraft Table is a proven source capture solution configured to address your specific air quality issue. This self-contained air filtration solution incorporates the patented DualDraw symmetrical airflow of a perforated work surface combined with a modular filtration system. Filtration on every table is configured based on the customer application and specifically addresses the hazard generated from an operator’s particular process: metal dust, wood dust, composite dust, organic dust, pharmaceutical dust, welding fume, cutting smoke, adhesive odours, and various other airborne hazards are all effectively captured and contained with our configurable and versatile solution. Each unit is covered by a multi-year warranty and incorporates DualDraw’s signature patented airflow design for optimal performance.

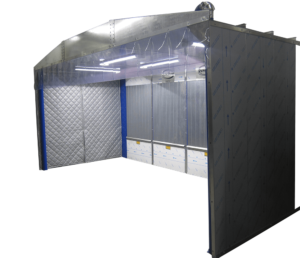

DualDraw Downdraft Booths include the signature DualDraw patented

perforated work surface and vented back stop to capture dust or fumes.

The downdraft booth style (TB) allows for maximum containment of dust and fumes through its three sided

enclosure that surrounds the downdraft work surface and vented back. The enclosed workspace of the booth

design significantly decreases risk of cross drafts and directs airflow in a highly efficient manner. For these

reasons, this style of equipment is an optimal choice for some of the most hazardous applications.

Similar to most DualDraw equipment, the size and filtration system of the desired downdraft booth are

always configured based on the particular customer application. In collaboration with the customer, an

efficient assessment of both the process being performed and hazard in question will result in the downdraft

booth specification best suited to address the customer’s concerns.

DualDraw Wet Collectors (the WC Series) are filtration systems designed to capture dust from processes

such as grinding, deburring, cutting, polishing, mixing, and many others. These are available as stand-alone

scrubbers, walk-in clean air stations, or as wet downdraft tables.

Our industrial wet dust collectors are typically used to address highly flammable or combustible dusts such

as aluminum, titanium, and magnesium. While these are some of the more common and dangerous metal

combustible dusts that these solutions can help safely contain, there is a broad range of other combustible

materials that can be mitigated using these solutions. In addition to combustible dust containment, Wet

Collectors are used to decrease fire risk from processes that may produce hot sparks or slag that would

otherwise ignite dry filter media.

DualDraw is the only industrial air pollution control company to have a published efficiency test of its specific

wet collector design. Results are readily available for review and we encourage customers to evaluate these

when making a purchasing decision about what system is going most effectively address their application.

Ask us today for the report.

DualDraw Walk-In Clean Air Stations (WI Series) are self-contained filtration rooms that enclose a wide variety of applications generating harmful dust, smoke, or fumes.

They are designed to address some of the most challenging indoor air quality problems.

Operators that work on large or asymmetrical parts oftentimes cannot easily place them under a hood, fume arm or on top of a downdraft table. Therefore, breathing zones are left unprotected, Walk-In Clean Air Stations operator health and safety is compromised, and cross contamination of plant equipment and processes by airborne dust is unchecked. Walk-In Clean Air Stations address these challenges.

A wide variety of filter choices are available for use in our Walk-In Clean Air Stations. Filtration selection is guided by a DualDraw sales technician in consultation with the customer. Depending on application, this may range from disposable panel

DualDraw Self-Cleaning Dust & Fume Cartridge Collectors are a rugged air pollution control solution used to address heavy-duty dust or fume

applications.

Systems come either attached to a downdraft table or as stand-alone collectors ducted to a variety of source capture hoods, tables, booths, and other emission sources located throughout a facility.

Systems are designed to be self-contained to minimize replacement air requirements and HVAC Customers with significant dust or fume producing applications typically will opt for Self-Cleaning Collectors due to the low maintenance requirements and the related low cost of replacement filters

over the life of the unit. Some common applications addressed with these types of collectors are cutting operations such as plasma, laser, or routing equipment.

Also frequently addressed are heavy-duty deburring, welding, or sanding. Various cartridge filter efficiencies, materials, and sizes are available depending on the particular customer application and operational requirements.

Top quality equipment

THE PROTECTION YOUR TEAM DESERVES

With 20 years of manufacturing mail screening equipment, we helped create the solutions that are considered the standard for safe and secure mail screening. Reduce anxiety and avoid the trauma of a mail screening incident through the use of technology we’ve perfected – and cost-effectively configured for hundreds of different customer environments.

BEST PRACTICE SCREENING PROTOCOLS

From digitization and electronic delivery, screening for narcotics, contraband, explosives, biological, chemical, and radiological agents, we build our services around your mailroom screening equipment needs. Whether we train your staff, help with hiring, or handle your entire mail operations, we have proven solutions that prioritize workplace and operator safety.